Sterilization

The combination of excellent bed fluidization, thermal treatment

and high pressure hasten the destruction of bacteria and germs

Sterilization can be accomplished in Processall Prestovac equipment.

Sterilization is excellent for:

• Powders for food and pharmaceuticals

• Agglomerates such as cocoa nibs or powder

• Grains and flours

• Plus many other miscellaneous products

The Processall Prestovac can be equipped to cool and condense any undesirable vaporized liquid. Also, it can be equipped to dry product if necessary. To suit process requirements, the Prestovac can be equipped with double- faced mechanical seals, special charging/discharging devices, and a sample valve capable of withdrawing product while the machine is running under pressure .

Sterilization of these listed products can be accomplished using three methods as appropriate.

The following is a list of these processes:

• Dry heating of the product with an appropriate hold time depending on the product

• Direct steam injection to achieve a desired temperature with a hold time

• Addition of alcohol with heating and hold time followed by vacuum drying to remove the alcohol

Dry heating does not use additional water which reduces the chance of product consistency changes. Also without additional water, no post sterilization vacuum drying is required. Use of heated air can improve overall count reductions.

Sterilization

Processall is capable of furnishing the sterilization equipment and the balance of the system including structural supports, process tower, feeding hopper, takeaway hopper, valve interlocks, load cells, etc.

Processall maintains a technical center in Mason equipped with many sizes of sterilizers. Also readily available is rental equipment for customer in-house testing.

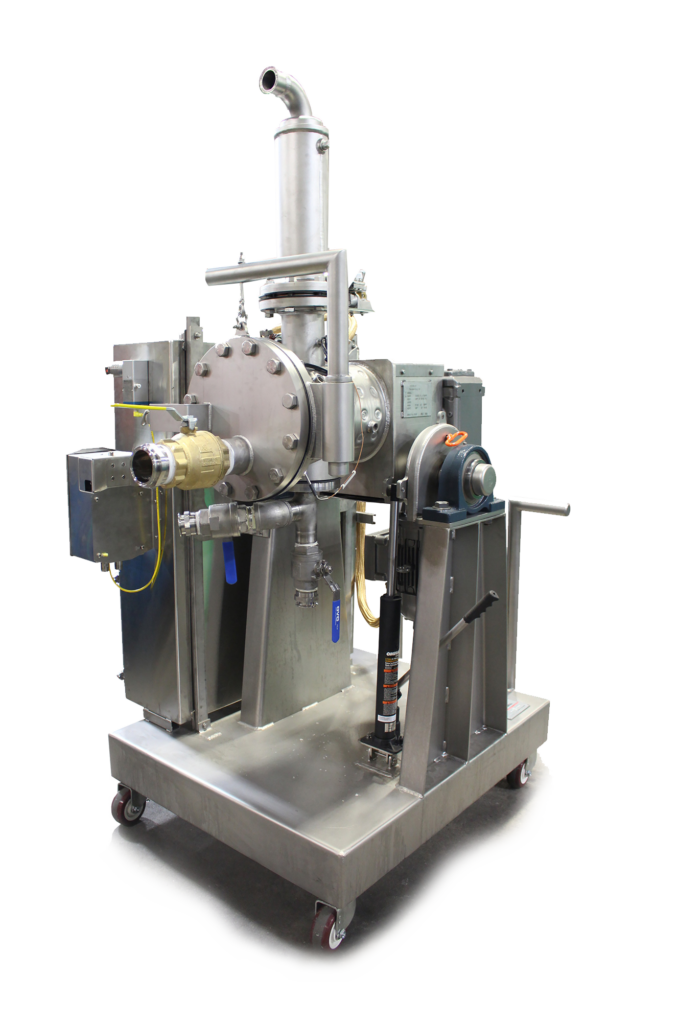

The Processall moisture recovery system can be used with the vacuum filter stack. This system utilizes a liquid ring vacuum pump to achieve high vacuum levels. A shell and tube heat exchanger discharges the condensate to a recovery tank. All product contact surfaces are 304 stainless steel except in the vacuum pump area. The entire unit is mounted on a stainless steel base with casters for mobility. Larger pilot plant reactors have many of the same design features found in production scale reactors such as stainless steel construction, vacuum operation capabilities, high speed mills, liquid addition capability, heat transfer jacket and many others.

The Processall Tilt-A-Mix laboratory processor is a rugged, flexible, and sanitary mixer/dryer/reactor of patented design. The Processall Tilt-A-Mix mechanical fluidized bed agitation principle is generated by the rotation of an agitator within the confines of a horizontal mixing chamber.