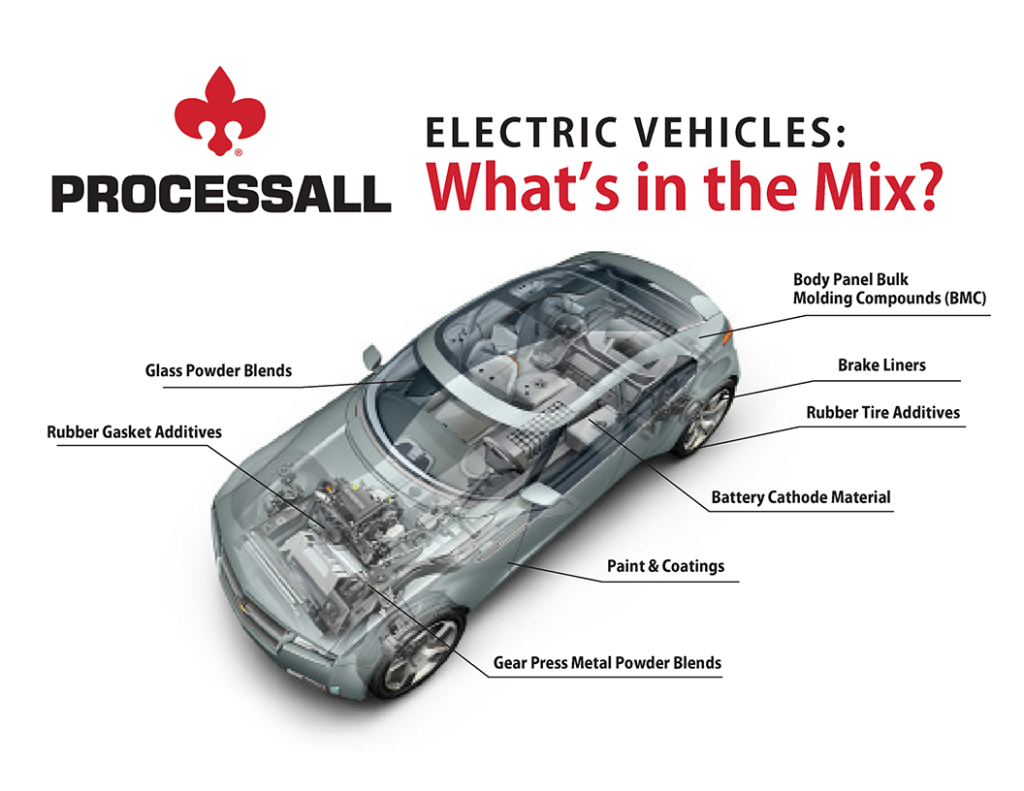

Anode Mixing & Cathode Mixing for Battery Manufacturing

Increase battery mixing production and decrease manufacturing costs

with faster, more efficient processing times.

TRUSTED SUPPLIER SERVING MORE EFFICIENT PROCESSES TO BATTERY INDUSTRY LEADERS ACROSS THE GLOBE

• Expert lab to production scale up for quicker concept to production

• Variable speed & multi-step blending operations, eliminating the need for additional equipment and unnecessary handling of the cathode paste

• Application-designed plows, choppers, and seals to ensure homogeneity of metal powder at the highest rates of long-term production

• Proprietary Proseals designed to handle abrasive metal powders to ensure longer production time

• Horizontal plow mixers perform operations concurrently or sequentially within the same vessel, minimizing the production floor’s footprint

Processall maintains a fully equipped testing facility at our factory in Mason, Ohio, designed to provide customers

with the data they need to develop their process, evaluate equipment, scale up, and identify the necessary

equipment to maintain desired production volumes.

We also maintain a rental fleet that customers can utilize for further testing at their facility

to minimize their startup costs for a new process.

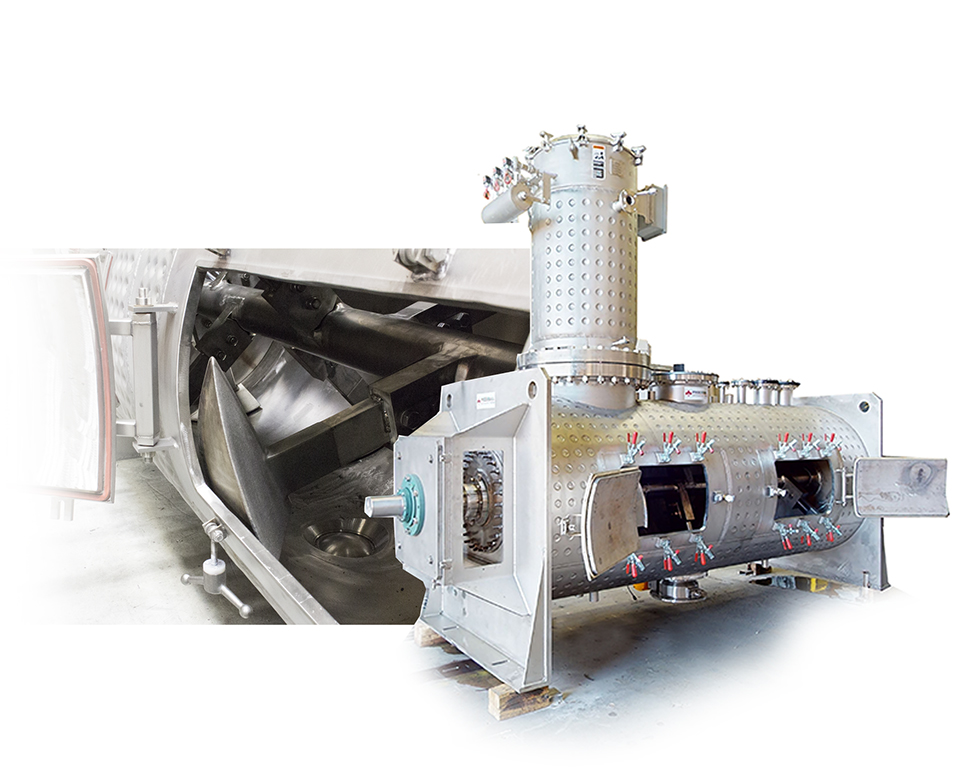

Processall is a leading manufacturer of horizontal plow mixers, plow pressure reactors, and plow vacuum dryers for a variety of industries

With four decades of improving customer processes, Processall is a leading industrial mixers manufacturer of horizontal plow mixers, plow pressure reactors, and plow vacuum dryers for various industries. Our line of industrial mixing equipment is carefully designed to meet the exacting requirements of your specific application and industry. It can be built to achieve specific results for your battery anode mixing & battery cathode mixing requirements.

Our products are manufactured in Mason, Ohio.

Processall provides comprehensive support from planning to installation.

At build completion, Processall conducts a customer run-off, giving confidence that the

equipment is running smoothly before shipment.

Our superior Armor Aftermarket team provides installation, startup, and training services, as needed,

helping to get production up and running as fast as possible.

Contact us with all your material processing questions

to find the right battery mixing solutions for your particular application.