Air Drying Plow Mixers

Drying touches many aspects of chemical manufacturing. Whether it be food production, pharmaceutical manufacturing, or even processes in the agrochemical industry, drying technologies are a vital part of the chemical production industry. This is because many chemical processes result in the formation of a wet filter cake. This cake typically must be purified and cleansed before it is sold to customers.

The initial precipitates are often full of impurities that form during reactions and these contaminates need to be removed following the filtration processes. The unrefined filter cake must be then purified. Often the material is washed with different solvents to remove any excess byproducts or unreacted materials from the product. These solvents range from a wide variety of organic solvents to water. After the purification stage, many companies are then left with a solvent-ridden material that needs to be dried. There are a wide variety of drying techniques on the market like air driers, microwave driers, radiant heat driers and vacuum driers.

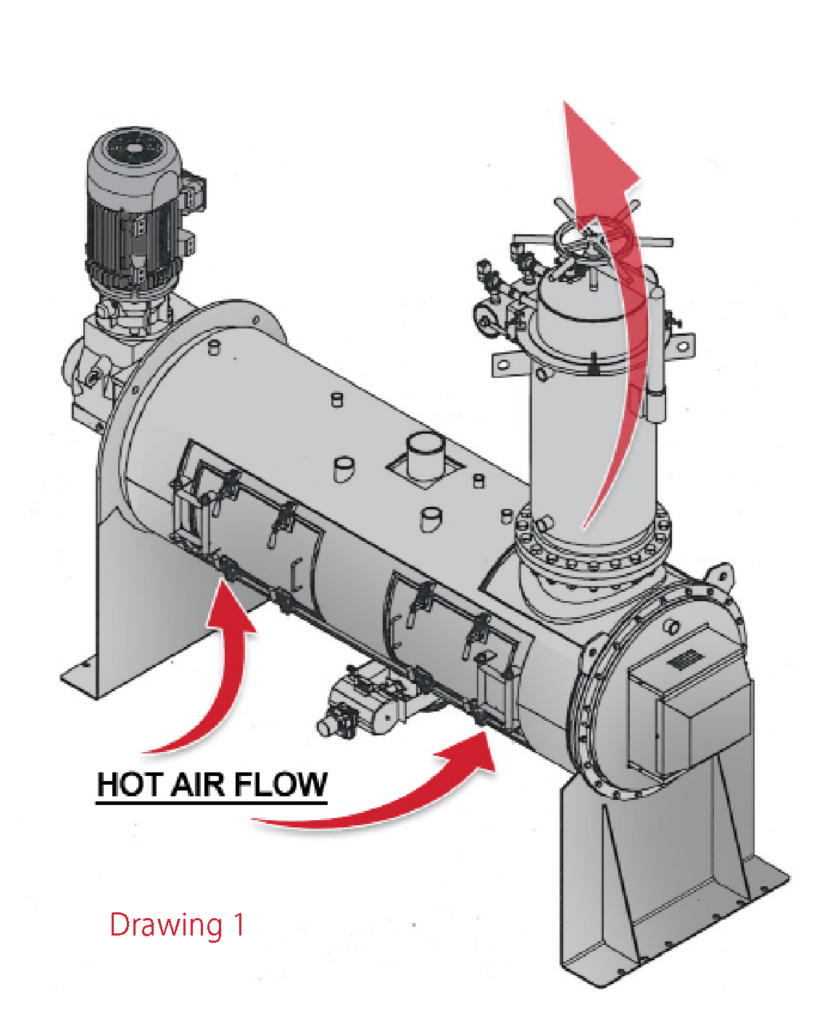

Few however, offer the speed, particulate size control, and customization features of plow share driers. Plow share drying can be done with either heated air, or a vacuum. In hot air, or adiabatic system, air is heated to a specified temperature and injected into the vessel ( Drawing 1). A vacuum, or non-adaibatic system, lowers the pressure in the vessel, thereby lowering the boiling point of the material. The jacket outside the vessel is then heated (above the new boiling point) producing evaporation.

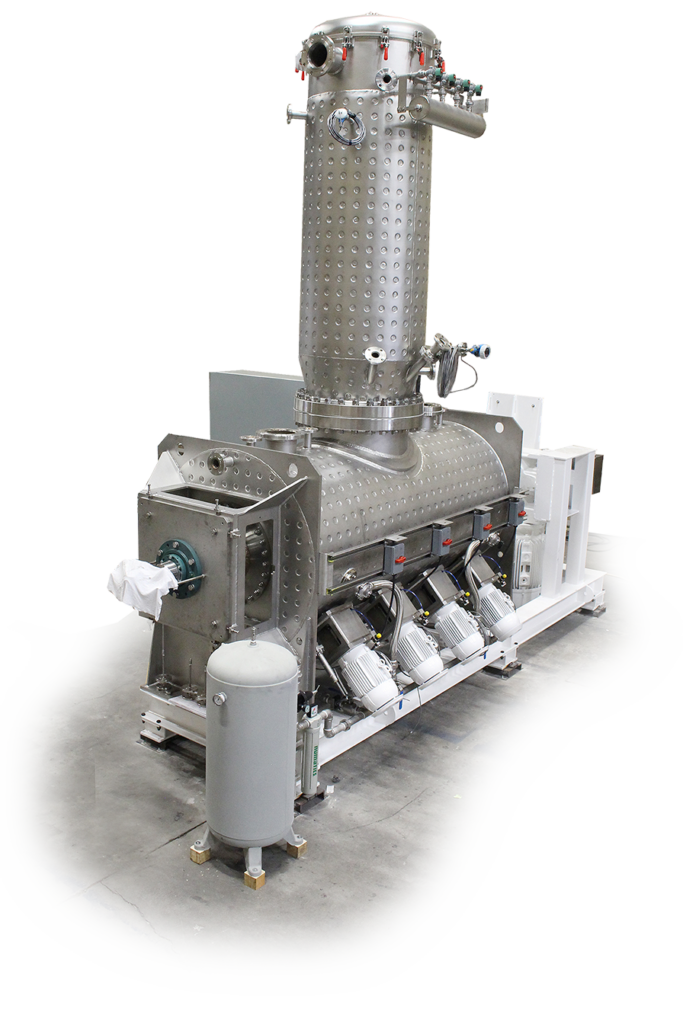

In either system the vessel is cylindrical and horizontal. A shaft through the center is mounted with mixing elements or plows. This mixing action enables particles inside the vessel to maximize their surface contact with the heated air or chamber walls. This in turn optimizes the heat transfer rate and evaporation, and faster drying times are achieved.

Vaporization of the solvent in an air drying plow mixer is done by heating the injected air into the drum to achieve the desired temperatures needed to achieve vaporization. The air injected into the drier is 100% dry to maximize the amount of transfer of moisture from the particulates in the fluidized bed to the injected air. The filter jacket then captures and removes this moisture.

Air drying offers several unique benefits over other technologies on the market. Some products are pressure sensitive and can become more reactive at lower pressure thus eliminating vacuum driers as an option. Besides pressure sensitive materials, air drying also can help with thermally sensitive products because the injected air can be controlled to achieve evaporation at lower temperatures. This style of drying is also most seen in granulation and agglomeration type operations where the plow mixers are used to help build particle sizes of materials and they need a gentler dry cycle not to damage the granules.

To help achieve particle size build up in granulation type applications, plow mills can be equipped with devices called choppers. These are high-speed blades placed on the side walls of the unit between the plows. Depending on the time used in the process, these blades can be used to either increase or decrease the particle size. For operations where particle size needs to increase choppers are used at the initial stage of the operation. During the initial stage, choppers are turned on to permit the liquid binding agent to help the particles agglomerate. Once the particles are built up the gentle air drying system keeps shear forces low.

During the drying operation, the unwanted solvents can be removed as they exit the dryer as a vapor. Processall’s excellent heat transfer can produce vapor volumes as high as 15 times the liquid volume. Therefore, it is useful to have a set of filters to separate the generated vapor from any potential entrained solid product. To prevent the filters from getting wet with condensed vapor, the filter housing is jacketed and provides heat input to maintain the vapor form. The filter can be cleaned by applied a pulsing mechanism that is directed down the inside of the filter dislodging any collected dry product. This type of filter unit is referred to as a Pulse-back Filter housing.

After reaching the final desired volatile content in the product, the material can be cooled for collection and final packaging without exposing the operator to dangerous conditions. Cooling of the product can also reduce the risk of fire or explosion by exposing the product to the atmosphere. The vacuum dryer can also be purged with an inert gas to further protect the product as well as the operator if the liquid being removed is a flammable solvent.

Processall’s Plow Mixing technology gives chemical manufacturers a leg up on the competition.

Listed below are some of the benefits of moving toward plow mixing technologies for chemical manufacturers.

• High heat transfer rate with coefficients upwards of 50BTU/(hr•ft²•°F) shortening drying time

• Lower vaporization temperatures protect thermally

sensitive material

• Can be customized with a wide variety of safety features to improve employee safety

• Ability to serve as both a reactor and dryer of materials thus reducing the need for multi-unit operations.

• VFD motors enable better control of the mixer speed and particle size

• Can be customized to include pulse back filters to reduce product loss during drying

• Optional Thermal jackets to allow for optimal

temperature controls.

Processall maintains a fully equipped testing facility in Cincinnati, Ohio designed to provide customers with the data they need to develop their process, evaluate equipment, scale-up, and identify the necessary equipment to maintain desired production volumes. We extend an open invitation to your product to our test center and get a “hands on” experience with our technology and capabilities.