Dry Liquid Dispersions

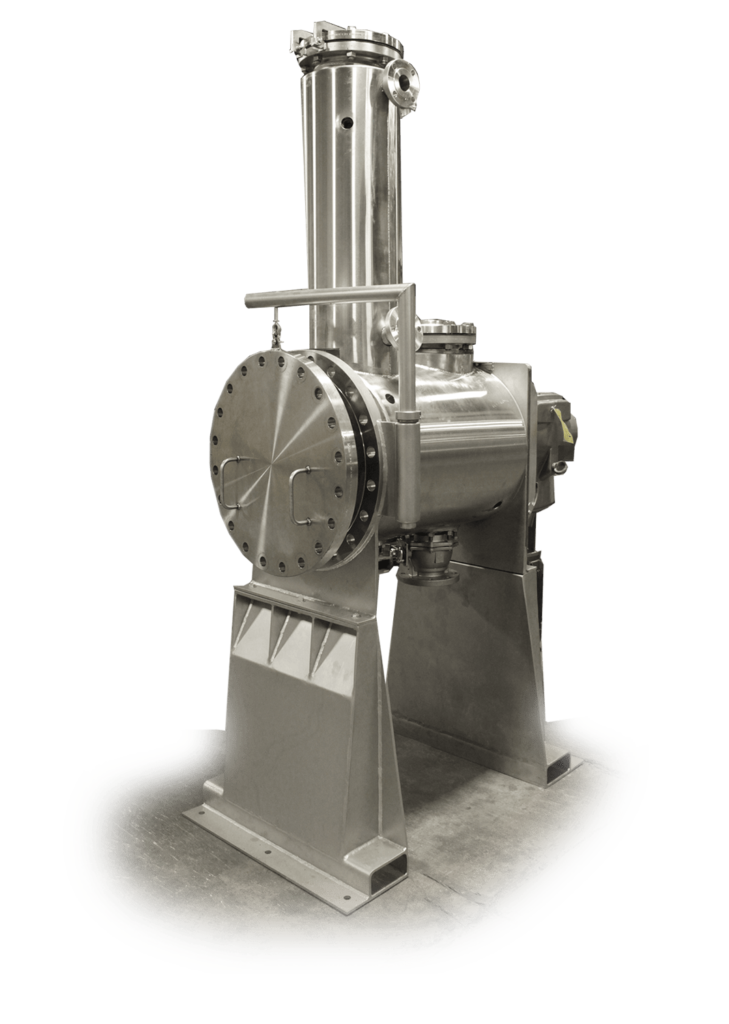

The mixing superiority provided by the Processall Mixmill device has allowed the evolution of a machine that is capable of processing beyond mixing to include drying and dispersing

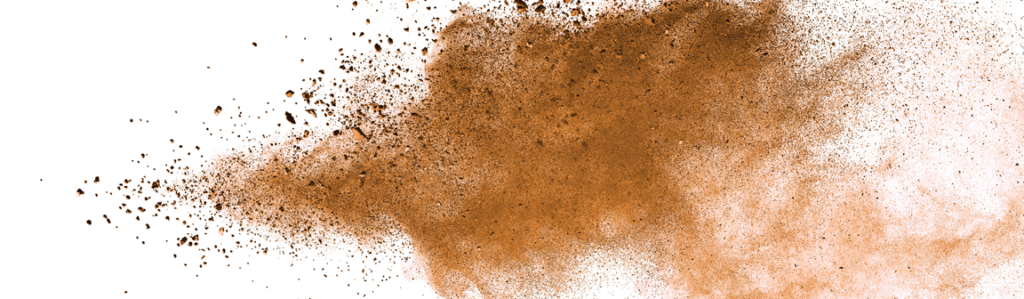

Dry Liquid Dispersions are processes where a viscous liquid is added to a carrier such as silica or other inert ingredients. The viscous liquids are difficult to weigh and completely add to various formulations. Making the Dry Liquid Dispersion yields a solid, somewhat like brown sugar in consistency, that allows for a more accurate and complete addition of the component to the formulation for further processing.

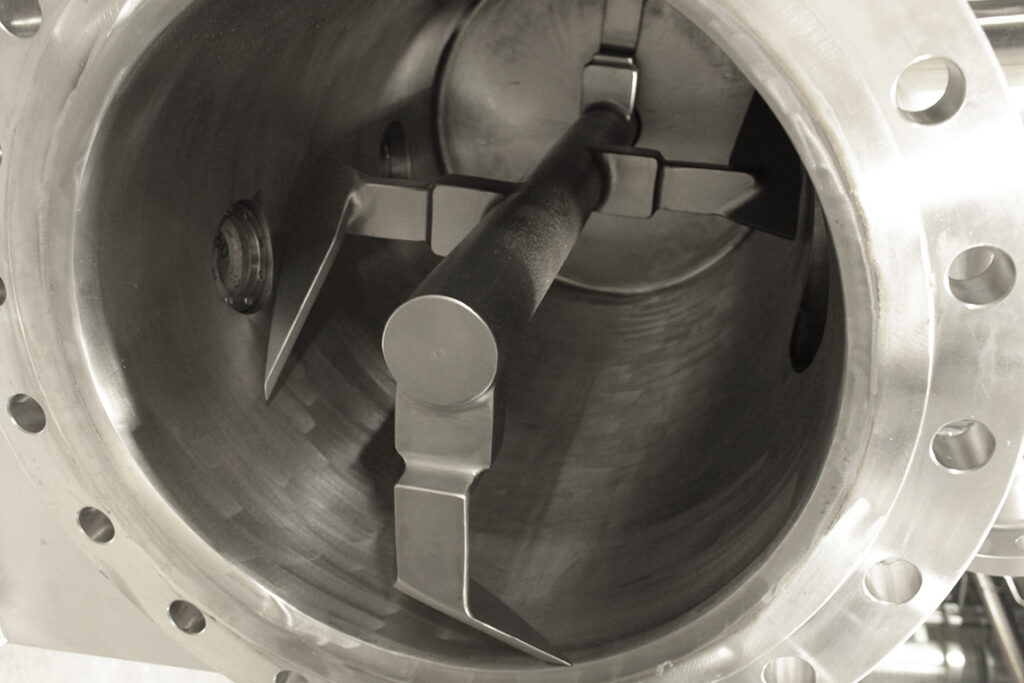

As the liquid should be added quickly, it is often useful to heat it. No-Clog nozzles, which close upon flow stoppage, are particularly helpful. These poppet-style valves allow for large capacity liquid flows and provide a flat sheet spray pattern. This pattern evenly spreads the liquid while the mill blades disperse it throughout the material.

Process testing requires consistent monitoring of power draw (from the main drive), along with product consistency. Dry Liquid Dispersions are sensitive to excess moisture, long cycle times and improper mill blade set up. Our testing lab can help fine tune the exact recipe by controlling shear and overall process time.

Processall is a leading provider of chemical processors, horizontal plow mixers, reactors, dryers, sterilizers and extractors. If you have any questions about our equipment and techniques, please feel freeto contact one of our experts.

Dry Liquid dispersions are often used in the making of rubber or plastic compounds. They utilize an inert carrier, such as a silica-based product, that is porous to hold liquid and facilitates a more manageable

consistency of the final product.

The inert carrier can hold roughly twice its weight.

As the dry carrier mixes, the liquid is added. Ports, lances, nozzles and more can all be used in various locations throughout the mixer. It is important to note that the liquid should be added to the dry carrier directly, not applied to the shaft or mixer walls.