Cellulose & Starch Derivitive Reactions

The Prestovac® is an excellent device to conduct

multi-step processing in one vessel

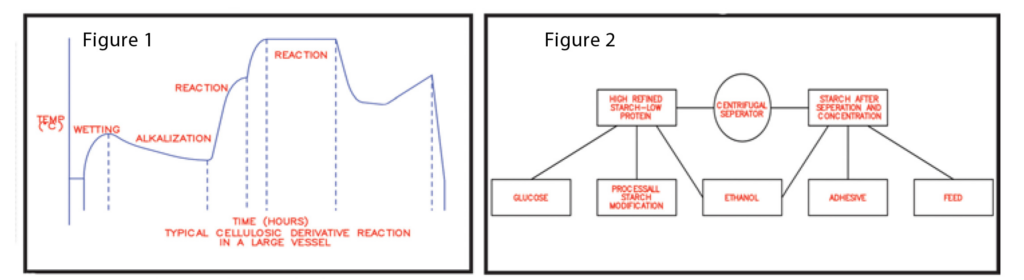

In a typical cellulose derivative modification process, the product is wetted and alkalized. A reaction step follows under pressure. With the excellent heat transfer capabilities an exotherm can be controlled easily without sacrificing the ability to quickly add the reactants. (See figure 1) A byproduct such as salt and other impurities can be dissolved and filtered in the same equipment prior to drying the product.

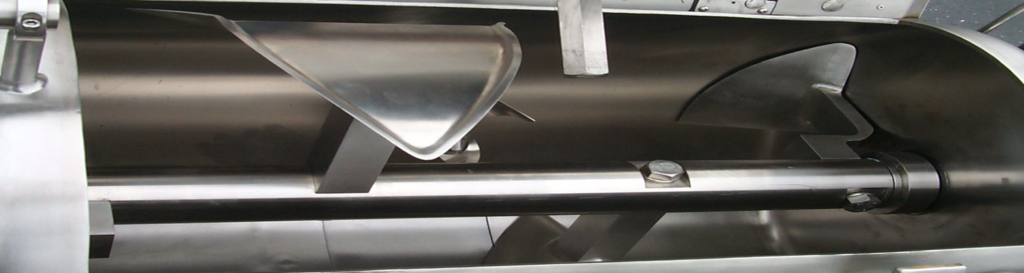

With chemical modification, gums can be provided with different properties. Alginates lack acid and calcium stability which can be changed by adding propylene oxide to form more acid stable propylene glycol. Also, by using Processall’s Prestovac reactor, cellulose can be modified to cellulose ethers by substituting hydrogen on the molecule with carboxyl group. Depending on the degree of substitution and the length of the polymer, different properties can be achieved to improve water solubility and reduce the unreacted fibers. Starch can be modified by wetting with catalyst and removing the moisture to have an even distribution of catalyst. This step is typically followed by a gas/solid chemical reaction. The final product is cooled and discharged after gas purging. (See figure 2)

The processing can be split in two vessels if higher production is desired. By using a Prestovac® in the first stage, the product can be alkalized and reacted. Subsequently the product can be moved to the Filt-A-Dry for washing and drying. Processall maintains a fully equipped technical center to demonstrate machinery and processing capabilities

Some of the benefits of the Processall system:

1. Multi-processing in one or two vessels.

2. Saves space due to size compactness.

3. Energy saving with excellent heat transfer

capabilities.

4. Environmental protection with a contained

processing approach.

5. Less material handling and transfer.

6. Easy to clean with the excellent

agitation capabilities.

7. Double face mechanical seal can be used to

contain the product.

8. Available with several options such as

liquid/solid or vapor/solid filters.

9. Single source supplier for the related

ancillary hardware.